YY180 High-Efficiency All-Purpose Hydraulic Oil Press

The YY180 high-efficiency all-purpose hydraulic oil press offers the ultimate solution for your oil extraction needs! Our well-designed hydraulic oil press is characterized by its high efficiency and convenience, allowing you to effortlessly extract pure edible oil from various oilseeds. Whether it's seeds, nuts, fruits, or grains, our versatile hydraulic oil press can meet all your oil pressing requirements, ensuring maximum oil extraction yield and purity.

Keywords:

Category:

TEL:

Detail

YY180 High-Efficiency All-Purpose Hydraulic Oil Press

(Specialized for Oil Sludge Press)

The YY180 high-efficiency all-purpose hydraulic oil press offers the ultimate solution for your oil extraction needs! Our well-designed hydraulic oil press is characterized by its high efficiency and convenience, allowing you to effortlessly extract pure edible oil from various oilseeds. Whether it's seeds, nuts, fruits, or grains, our versatile hydraulic oil press can meet all your oil pressing requirements, ensuring maximum oil extraction yield and purity.

I. KeyFeatures:

1. Energy-Saving and Efficient

- Energy-saving: The motor power is only 3 kW, requiring only 1 kWh of electricity per hour.

- Efficient: Standard single barrel can hold 100 kg of raw materials, and the double barrel option is available for purchase.

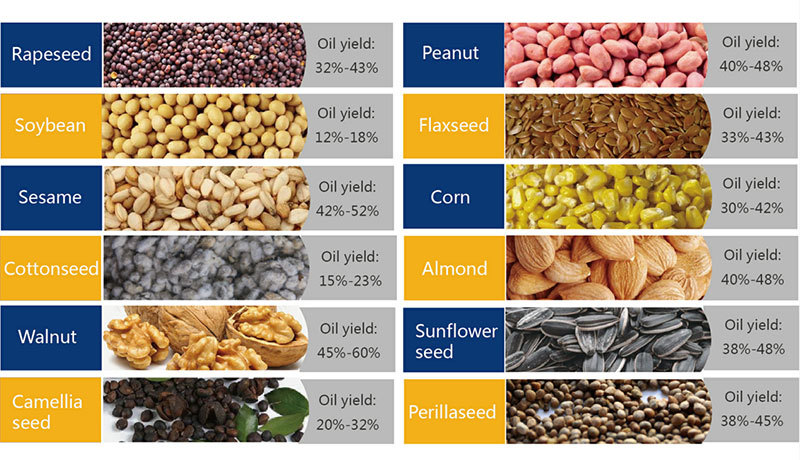

2. Versatility: Our hydraulic oil press is designed for various types of oilseeds and oil-containing materials. Whether it's sesame, soybean, peanut, or coconut, our machine can handle it with ease.

- In addition to pressing vegetable oil, this product can also press animal oil and even chemical waste. Contact us for special requirements.

- For certain oilseeds, secondary pressing is possible, and the oil extraction rate can reach up to 60%.

3. Easy Operation and Labor-Saving:

- Easy operation: The machine is fully automated, with automatic pressing and automatic returning.

- Labor-saving: One person can operate 3-4 units simultaneously.

4. High Yield and High Quality:

- High yield: The pressing speed is fast, with only half an hour needed for most oilseeds in hot pressing. The residual oil rate is low, and for some oilseeds, the residual oil rate can be controlled as low as 5%.

- High quality: The oil obtained from cold and hot pressing can be directly consumed, preserving the natural flavor and nutrition of the oil to the maximum. For special storage requirements, additional refining equipment can be provided.

5. Sturdy and Reliable:

- Made of high-quality materials and precision craftsmanship:

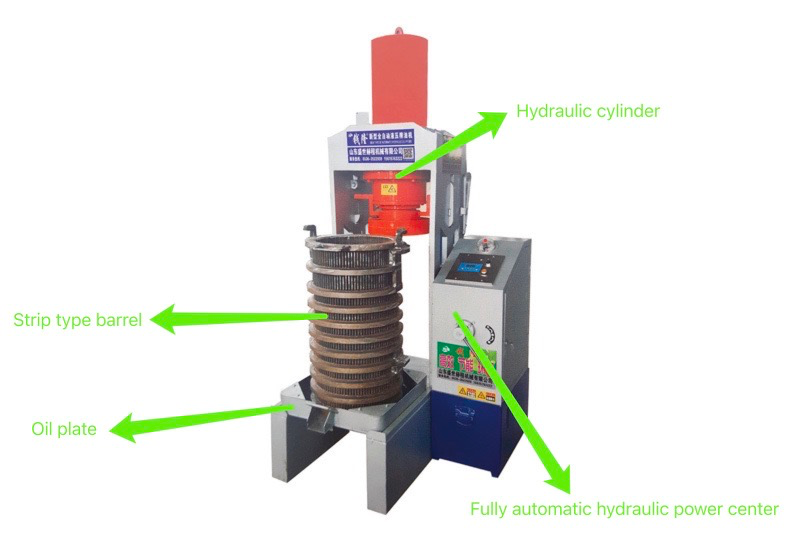

- The strip-type barrel is made of high-quality and thick steel, ensuring durability and long-term performance, suitable for various high-strength oil pressing scenarios.

- The hydraulic core component oil cylinder is made of top-quality alloy steel, which is currently the best material in China. It can withstand high pressure and corrosive substances during the oil pressing process, and prevent oil and metal reactions, ensuring the purity and quality of the oil. The raw material cost is more than three times that of market competitors, and it is the preferred standard for domestic high-thrust hydraulic equipment. The highest thrust standard currently available can reach 1800T, which can achieve excellent repressing effects for chemical materials and special vegetable oil waste.

6. Safe and User-Friendly:

- Safety features such as stroke overload protection and pressure sensing ensure safe operation and stable production.

- In addition to automatic processing, the machine also features manual operation for convenient adjustment of loading and unloading positions. The compact design saves space and facilitates placement and storage.

II. Main Structure and Product Parameters

Product Model :YY180

Maximum Pressure Capacity:300T

Working Pressure :60Mpa

Barrel Diameter :Standard: 39cm (Customizable: 39-60cm)

Barrel Height :Standard: 80cm (Customizable: 50-80cm)

Power Supply :380V/220V

Motor Power:2.2Kw

III. Equipment Working Video

IV. Pre and Post Oil Pressing Equipment

|

Oil Pre-processing equipment |

Oil Post-processing equipment |

||

|

液压包饼机 Hydraulic Cake Packaging Machine |

|

离心式滤油机Centrifugal Oil Filter |

|

|

预榨机 Pre-press machine

|

|

碎饼机 Crusher for Cake Residue

|

|

|

不锈钢滚筒电磁炒锅 Stainless Steel Drum Electromagnetic Stir Fryer |

|

千层双压式精滤滤油机 Pressure Type Multi-Layer Precision Oil Filtration Machine

|

|

|

花生磨糁机 Peanut Grinding Machine |

|

气压滤油机 Pneumatic Oil Filter

|

|

|

茶籽粉碎机 Tea Seed Crushing Machine |

|

油脂精炼设备 Oil Refining Equipment

|

|

|

全自动导热平底炒糁锅 Fully Automatic Conductive Flat-bottom Stir-frying Pot |

|

冷冻脱蜡设备 Frozen dewaxing equipment |

|

|

无压蒸汽锅炉 |

|

半自动防盗盖封口机 Semi-Automatic Anti-Theft Aluminum Cap Sealing Machine

|

|

|

配套灌装机系列 Filling Machine

|

|

||

|

负压熬油锅

|

|

||

V. Reference Production Line Process for Related Products

- Peanut Oil Production Process and Production Line

- Soybean/Rapeseed Oil Production Process and Production Line

- Camellia Oil Production Process and Production Line

- Sesame Oil Production Process and Production Line

- Peanut Oil Sludge Production Process and Production Line

VI. Real Scene Pictures of Customer Processing Production Lines

CONSULT ONLINE

RELATED PRODUCTS